BEST SOLUTION

PROVIDER

Thermal Insulation

-

To guarantee a correct process cycle, the condition of the media within the pipes must remain within the set limitations (e.g. temperature, viscosity, pressure, etc.). In addition to the correct isometric construction and fastening of the piping, the piping insulation also has an important function. It must ensure that the heat losses are effectively reduced and that the installation continues to operate economically and functionally on a permanent basis. This is the only way to guarantee the maximum efficiency of the process cycle throughout the design service life without losses as a result of faults.

Principially, a thermal insulation structure for piping consists of an appropriate insulating material, usually covered by sheet metal cladding. This protects the pipe and the insulation from external influences such as weather or mechanical loads.

Spacers are also essential with insulation material such as wired mats , which do not offer sufficient resistance to pressure to hold the weight of the cladding and other external loads. These spacers transfer the loads from the cladding directly onto the pipe to be insulated. in case of vertical piping, support structures are fitted to take on the loads of the insulation and the cladding. In general, support structures and spacers form thermal bridges.

HVAC Insulation – Pipes

For the HVAC (Heat Ventilation Air Condition) applications onboard a ship it is most common to use Pipe Sections or Marine Lamella Mats to insulate the pipes. The aim is to prevent heat loss in heating systems and warm water supply. It is necessary to supply heating and warm water also in the last cabin away from the source.

The benefits of correct thermal insulation for piping include:

- Reduction of heat losses

- Cost savings

- Reduction of CO2 emissions

- Frost protection

- Process control: ensuring the stability of the process temperature - Noise reduction

- Condensation prevention

- (Personal) Protection against high temperatures

Airducts

Today many requirements are made on air ducts. Most important is that the comfort on board the vessels or platforms living quarters is considered and that no compromises are made to the demands on fire safety. In connection with ventilation of cabins and other rooms it must furthermore be ensured that no condensation is formed and that the required temperature is maintained all the time. This is obtained by using one of the ROCKWOOL SeaRox products in the correct thickness

-

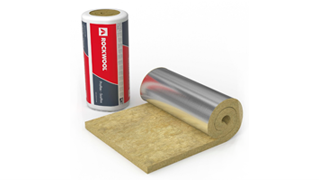

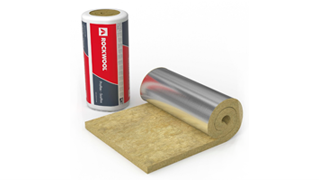

SeaRox WM 620 (ALU)

90kg/m3 -

SeaRox WM 640 (ALU)

105kg/m3 -

SeaRox SL 340 TB

80kg/m3 -

SeaRox MA 7000(ALU)

26kg/m3 -

SeaRox WM 950 (ALU)

80kg/m3 -

SeaRox SL 720 (ALU)

110kg/m3 -

SeaRox LM 900 ALU

32kg/m3

TOP